The Concepts and Devices

Background

Currently produced internal combustion engines and fuel delivery systems are very much based

upon concepts which originated with the work done on the first factory produced vehicles built by

Karl Benz in the 1880's. They can be seen to be 19th century technology with more modern

refinements bolted on to attempt to increase efficiency and power. But it must be said that internal

combustion engines waste much more energy in dispersing heat or wasting fuels than in actually

driving a car. The nature of internal combustion will allow only for a 30% efficiency by the very

nature of the physics of its operation, which uses heat to expand gases to drive pistons. But even

more wasteful is its use of fuel to produce the heat. Because liquid fuel does not burn,

evaporisation and vaporisation must be used to change the state of the liquid to a vapor, and

therefore allow ignition to take place. Liquid petrol or diesel will not ignite.

Any fuel injection unit or carburetor that delivers a liquid, or even atomised liquid to the combustion chamber, does not fully vaporise the fuel. The vaporization of this liquid to allow for ignition must take place over a period of several milliseconds. There is not enough time to normally convert more than 10% of the fuel into vapor. So the remainder gets cooked within the combustion chamber, to form carbonous deposits within the engine, or gets sent out through the exhaust. That leaves around 90% of the fuel basically wasted.

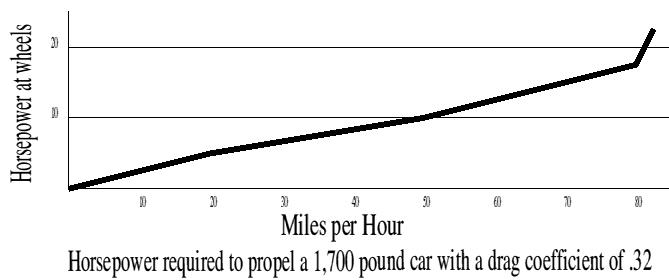

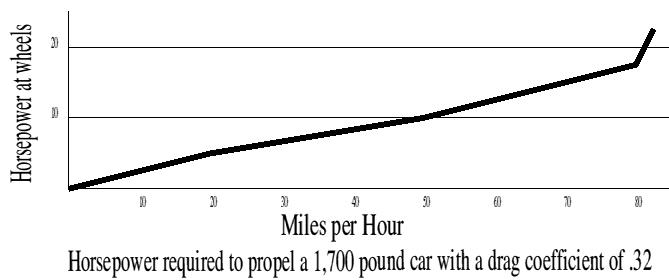

The veracity of this can be demonstrated as follows: the mechanical equivalent of 1 horsepower is 2,545 BTU. Each gallon of fuel, notwithstanding variations in composition, has approximately 124,000 BTU. A 1,700 pound car with a drag coefficient of .32 (which is a little on the high side in comparison with the most aerodynamic cars) travelling at 50 MPH would require only about 10 hp to maintain speed. If that car got 25 miles per gallon, it would use 2 gallons in an hour. The mechanical equivalent of 1 horsepower in BTU is 2,545 BTU/hr. 10 hp over an hour would therefore be 2,545 x 10 = 25,450 BTU. 2 gallons of fuel at 124,000 BTU = 248,000 BTU. Therefore, 222,550 BTU (248,000 - 25,450) is being wasted. The scope for improvement is enormous in this case, on the order of 975%.

Most attempts by the vehicle manufacturers to increase fuel efficiency are centered around two approaches: reduction in weight, and refinement in engine design and fuel delivery systems. The reduction in weight has reached an effective plateau, as long as conventional metals are used in construction. Engine design has also reached somewhat a plateau, although there always seems to be continual tweaking and development which leads to marginal gains in performance and/or economy. Fuel delivery systems become more and more micro-processor controlled, but again, this can reach a plateau as long as conventional delivery of fuel is maintained, although finely controlled.

An Alternative - the Fuel vaporizer

One area of improvement which has almost entirely been overlooked by the motoring companies is

in the treatment of the fuel before being burned, i.e., vaporisation. By vaporising the fuel before it

enters the combustion chamber, we can neatly circumvent the problem of not having enough time to

thoroughly vaporise it after it has entered the combustion chamber. Remember, only vaporised

fuel will burn. By doing this, we can effect substantial savings in fuel economy and pollution reduction.

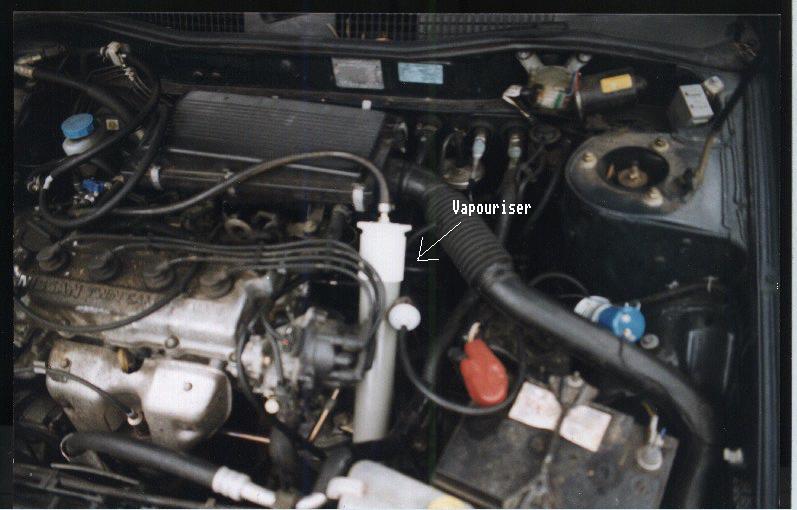

The Low Pressure Vaporizer in a pvc construction installed in a Nissan Primera

We offer two vaporizer versions, and also information on how to build your own. The core concepts of the devices come from George Wiseman of British Columbia, Canada. He publishes information on some devices and some parts, but he has not patented the infomation, purposely. I have taken these concepts and done further experimentation and development, and have come up with my own versions, again, which are not patented. The principles are the same between Eagle Research and ours, but the design and operation differs significantly on a number of points.In both instances, the devices only modify or add to the usual fuel delivery of either the carburetor or fuel injection system. No existing pollution controls are modified or removed, so their use and installation is completely legal. In fact, the more pollution control devices exist on the vehicle, the easier it is to install the devices. The only question may be in terms of manufacturer warranties, but these should not in reality be affected, as we are not mechanically altering the carburetor or injection unit; but we cannot guarantee the reaction of all dealers to the device. Indeed, in the U.S., no car company can legally invalidate a warranty on the basis of any aftermarket add-on. If the customer is worried about this, we would recommend they purchase the manual only, and show it to their dealer first, in order to obtain their approval.

The Fuel vaporizer will work on almost any vehicle using liquid fuel - carburetor, fuel injection, petrol, turbo diesel (not nornally aspirated, unless an air pump is fitted), or alcohol. The gains to be expected with this device can be in the region of 50% for the petrol or gas versions, or broadly 30 - 70%, but the diesel version will get about %15, because of the difficulty in vaporizing diesel fuel. In the fuel injected versions, usually no modification is required, except to tap into the intake manifold, which can usually be done via an existing tap, such as a pcv valve, which usually means only splicing into an existing hose. If there is no pcv valve, or some such tap, the servo brake vacuum hose can be used: as long as the unit is installed properly, very little vacuum is required by it, and so there will be only a very slight drop in pressure to the brake servo.

The High Pressure Model of our Vaporizer Kit, supplied in a narrow vessel

High Pressure Model in the standard size vessel

The most common version of the vaporizer consists of a reservoir made of stainless steel approximately 10cm in length and about 7cm wide. This is what we prefer in our own installations, and what we sell in our 'kits'. This type is used for engines of from less than 2 litres to larger than 4 litres - if you have a large engine (4+ litres) you can use more than one, but it is not absolutely necessary. A second type of vaporizer body uses common pvc pipe, and if you want to build your own it is more easily obtained from any plumbing supply or DIY store. This type will usually require an additional small vapor expansion tube - the stainless steel version does not. The only requirement is that the reservoir must have a fuel line run below it when the fuel exits through it, and for this reason we usually recommend that it be put in the return hose to the fuel tank. In case of an accidental collision of the vehicle, the reservoir holds less than 1/20 litre of fuel which might be spilled, and so the hazard is not great. However, it should not be mounted in very close proximity to the exhaust system. The parts themselves are not difficult to obtain, and there is some leeway for substitution for the parts recommended in the manuals, should the customer decide to build their own.

Pollution reduction of carbon monoxide and nitrous oxide is about 90%. The Low Pressure version as sold includes the reservoir, 2 in-line valves used for regulation, and the required fuel hose and T-connectors, and the manual. The price for the Brightman version is $140.99(GBP70.50). For most vehicles built after the early '90's, because of restrictions in the return hose, or because of pressurization of the fuel system, an additional float valve and 3 way fuel valve must be installed on the incoming feed to the reservoir. This turns the unit into the High Pressure version, and hence the more expensive cost. The High Pressure version price is $240.99(GBP120.50).

If you do not know what kind of vaporizer to build or obtain from us, please just send us an email stating what kind of vehicle you are intending this for. We will let you know.

Should you have trouble in obtaining any parts if you completely build your unit from our manuals, you can obtain any individual components through us. You can see these on the order pages under 'Individual Components'.

Fuel Savings

In summary, the carburetor enhancer should furnish improvements in the range of 20% in MPG. The vaporizer should furnish between 30-70% increase in MPG over your current amounts in petrol engines. TurboDiesel engines will increase about 7-14% in MPG. The water injector furnishes only about 1 mile per gallon.

Pollution Reduction

The following shows results of a sample installation in the reduction of carbon monoxide, carbon dioxide and hydrocarbons.

Gases Normal with Carburetor with Carb Enh. with

Enhancer & Water Inj. vaporizer

CCarbon Monoxide

(cor.) 9.00 8.9 5.24 0.17

Carbon Dioxide 1.08 1.18 9.23 5.70

Hydrocarbons (ppm) 382 285 132 220.0

As you can see, there is an increase in carbon dioxide, but a significant reduction in the main toxic gases. There is evidence, although it is difficult to establish precisely with present measurement technology, that the vaporizer reduces particulate pollution in diesel vehicles. This is evident if doing a physical sight test before and after installation, which is still the only standard way of measuring particulate pollution.

Performance Increase

With the increased fuel efficiency, there is a corresponding increase of power and torque. We have not conducted engine bench tests, but provide the results of 0-60 acceleration tests on a 1.4 litre Citroen BX RE:

0-60 in Seconds

Normal with carburetor with Carb Enh. with

Enhancer & Water Inj. vaporizer

12 11 10.5 ~9

Another 0-60 test, this time with a 1989 Volkswagen Passat, 1.8 litre (1781cc), Single Point Fuel Injection (Bosch Multi-Jetronic):

Normal with 1 with 2

vaporizer vaporizers

13.8 10.5 10

To give you an indication of the performance increase, VW gives the following 0-60 times for this model of their engine range:

Engine size (cc) Horsepower 0-60 times (seconds) 1595 53 15.5 1781 66 13.8 1781 82 11.3 1984 100 10.1

Without dyno testing, we cannot give actual horsepower increases, but the performance times would indicate an increase of about 50% in horsepower. At the same time, in this particular installation, there is the 57% increase in MPG, and a 90% decrease in pollution. Not bad, is it?

Magnetic Enhancement

As an inexpensive but significant upgrade, we offer a magnetic enhancement kit for vaporizers. This includes some neomydium (very powerful) permanent magnets which are strapped to both the fuel and vaporizer hoses to allow for improved combustion, theoretically on the principle of ionisation and polar attraction.

These work on any vaporizer sold in the market - these are simply magnets, of a certain size and polar configuration, that when used in certain positions and polarities will provide a further 10-15% improvement in fuel consumption. These kits are US$45.99 or £22.99.

Summary

We supply completed units for you to install, manuals to build one's own systems, or units installed by your own garage. We also supply the individual components, should you wish to purchase a manual and then purchase only those components you do not wish to make or obtain yourself. Should you wish to use a garage or installer, additional charges would be made by them in installation; a reasonable benchmark for this would be 2 - 4 hours, times the normal hourly rate of the garage. If the customer was not satisfied with the installation, the cost of the device would be refundable, but not the time of the garage in installation and deinstallation time costs, as it must be recognised that the garage is acting as a third party. The Wiseman manuals, obtainable directly from George Wiseman at Eagle Research are fully detailed 36+ page manuals from the original inventor in Canada. Our manuals are different in design, are more basic and cheaper as a result. We have developed our own enhancements and other devices as can be seen in our menu on the left. Prices for both the manuals and devices are in the order section - just press the Order button in the menu. The manual specific to the vaporizer type ordered is included with the kits that we sell.

The 'kits' have the completed components supplied, with each installation consisting of 1 or two main components along with control valves, T connectors and other fittings: enough for the average installation. Only fuel hoses are not supplied because of their bulk - these can be obtained at any local auto supply store, or are available from us as a separate item. There is nothing to build - only install. If additional components are required, we will swiftly supply them, or they can be easily obtained locally from auto supply stores.

Installation times for an inexperienced customer are: Water injector 15 minutes Carburetor Enhancer 30-60 minutes vaporizer 2-4 hours

Devices can be removed, or circumvented from operation in a vehicle in case of malfunction in 5 - 15 minutes, either with no tools or at most a pair of pliers.

In vehicles which use electronic fuel injection, the increased efficiency creates an increase in oxygen output in the exhaust - basically, less pollution. This affects lambda sensors, which will read the increased oxygen output as meaning the fuel/air mixture is too lean, and therefore pump more fuel through, negating somewhat the economy benefits of the vaporizer. If nothing is done to compensate for this, fuel economy benefits can be limited to about 10-15% - in some cases. However, a simple electronic circuit has been developed which can be used to compensate the reading coming from the oxygen sensor before it is picked up by the fuel injection computer. It can be built by any user with a small amount of experience in electronics. The plans come from George Wiseman, and can be purchased for an additional $10, or the complete EFIE constructed circuit, at $50. Please order these directly from Eagle Research . With this circuit, gains would increase to the 30%-75% obtained with carburetor installations.

Another alternative to the EFIE is the lambda or oxygen sensor simulator - this allows the use of several devices without further adjustment. These can be found at http://www.magnumtuning.com . These simulate the lamdbda sensor, without trying to calibrate the signals coming from it - an advantage if more than one fuel saving device is used.

To ascertain whether an EFIE or simulator is necessary, contact us. Generally, for vehicles manufactured after 1990, they will be necessary.

Delivery times are around 4 weeks for devices (because they are modified to the vehicle they are going to be installed in) and 1-2 weeks on manuals. Please note that all deliveries for vaporizers are done in 2 parcels that are sent simultaneously - this is cut down on postage costs from the UK, as a preferential rate is given for parcels that are less than 2 kgs.