Petrol/Diesel Master reduces friction to a level of 0.01% and protects metal to metal surfaces against abrasion and thermal damage.

Introduction to Petrol/Diesel Master

Petrol/Diesel Master is a new concept in lubrication technology.

Petrol/Diesel Master is a mono molecular hydrocarbon surface modifier, which can be added to all existing mineral and synthetic lubricants in the ratio of 5% (one part in 20). 1:20 dilution is all that is normally required, but higher concentrations up to 1:10 can be used. It represents a major breakthrough in the field of liquid engineering to reduce friction and protect against abrasion, humidity and thermal damage on metal surfaces. It is not a solid such as PTFE or Molybdenum Disulphide, graphite, silicone, lead, copper, or fine metal particle, zinc or plastic. There are no large amounts of calcium phophorous or barium. Petrol/Diesel Master is entirely free of resins and congealing agents.

If used in fuel, Petrol/Diesel Master will purge the entire fuel system. It cleans the injectors and prevents carbon build up. Protection is also afforded to the injectors. Lubrication is added to the valves and the valve seats. The initial purge is accomplished by adding 50ml of Petrol/Diesel master to your fuel tank when you fill or top up. After the first tank of treated fuel, a further 50ml is added to the second fill up. Thereafter, the dosage is reduced to 25ml for every 50 litres of fuel that is put in the tank.

Petrol/Diesel Master bonds to metal surfaces above 50 degrees Centigrade and creates a mono molecular surface, up to 0.05 microns, to form an extremely low friction surface which is able to withstand excessive temperatures and pressures. It does not affect design tolerances.

It extends the life of all metal surfaces and maintenance intervals can be extended.

It can be used as a superior releasing agent, and impregnates corroded and seized parts.

Petrol/Diesel Master Benefits

1. Compatible with mineral and synthetic oils and most Hydraulic oils.

2. Blends with most greases, pastes, 2 stroke fuel oil, cutting oil, chain oil, compressor oil, axle oil, drilling lubrication, tapping fluids, hydraulic oil, mining fluids, fuel oils, scourable oils, coolants, antifreeze (not glycol based fluids). Soluble cutting fluids, penetrating oils, flushing oils, general purpose lube oils.

3. Petrol/Diesel Master bonds to metal surfaces in engines and machinery (pressure and heat at 50 degrees centigrade). Dip and bake at 190 degrees centigrade.

4. Leaves tolerances unchanged and has a nil electrical resistivity.

5. Works dry, under water, in a vacuum and from minus 50 degrees centigrade to plus 400 degrees centigrade.

6. Petrol/Diesel Master coefficient of friction pin on plate is 0.01 at +320 degrees C.

7. Operates up to 20,000 N. Has acidity and toxicity and oxidation of normal oil.

8. Petrol/Diesel Master is compatible with all metals, manufactured into the following products: bar, mesh, insulated wire, laminates, staple fibre, film, chopped fibre, lump, flocculent, rod, flake, microfoil, powder, liquid, sheet, microleaf tape, paste, single, crystal, fabric, granule, wire, metallised film, monofilament, non-woven fabric, tiles, honeycomb, tube, foil, plate, ball, pin roller.

9. Petrol/Diesel Master when dry does not: flake, melt, crack, scuff, drag out, contract, migrate or wash off.

10. Petrol/Diesel Master helps to prevent: seizure, galling, vibration, noise, frictional heat.

11. Petrol/Diesel Master improves: loading on bearings, cutting tool versatility, product finishing.

12. Petrol/Diesel Master materials: some manufactured components and materials may now be used in applications previously thought of as unsuitable.

13. Petrol/Diesel Master is manufactured solely in U.K. to the quality of BS5750 and ISO9002.

Petrol/Diesel Master Savings:

1. Reduces exhaust emissions up to 80%.

2. Improves compression up to 16%

3. Saves petrol, diesel fuel up to 12%.

4. Reduces oil consumption up to 20%.

5. Improves BHP up to 8%.

6. Improves life of oils 100%.

7. Reduces vibration up to 50%.

8. Reduces operating temperature 20%.

9. Extends the life of filters up to 20%.

10. Improves torque value up to 12%.

11. Improves frictional flow rates up to 15%.

12. Saves electrical power up to 14%.

13. Improves Nm Rating on Gears up to 12%.

14. Improves cutting tool life up to 200%.

15. Reduces operating noise up to 10%.

16. Improves production output up to 20%.

17. Extends the battery life on tools 12%.

18. Increases operating speeds up to 10%.

19. Reduces all round friction up to 95%.

20. Reduces weight loss on bearings by 50%.

21. Extends the machine life by up to 33%.

Petrol/Diesel Master When Used In Fuel or Oil

Petrol/Diesel Master reduces emissions up to 80%. It improves fuel economy up to 12%. It is a low cost, highly cost effective method of pollution control and fuel savings. It treats the fuel itself, raising octane levels and treating the injectors, therefore reducing significantly carbon build up.

Petrol/Diesel Master vastly reduces particulates and emissions including carbon monoxide, hydrocarbons, nitrous oxides and black smoke to below Euro standards. It is very cost effective, improving fuel economy by up to 12%, giving a net saving on total fuel cost over the cost of the product of at least 5%.

Other benefits: increases power output by up to 20%. Lowers the operating temperature of the engine. Reduces the noise level and drag in th engine. It can allow the use of lower octane fuel in high performance engines normally requiring high octane fuel.

Significant benefits can be gained in adding Petrol/Master to the following machinery:

Add Petrol/Diesel Master after an oil or hydraulic fluid change and monitor the difference in performance. It can also be added to equipment in operation. The life of the machinery will be increased as a result of reduced friction and yields a considerable saving in energy. Apart from the time saved, maintenance costs and replacement part costs are reduced.

Technical Information

Petrol/Diesel Master surface modifier is monomolecular and this quality provides a surface which rejects other molecules from binding to the metal and creating unwanted friction.

The surface modification also extends to metallic debris in equipment and renders such deposits less harmful, as the debris is coated as well. Oil ways are kept clear and filtration is not impeded.

Petrol/Diesel Master, unlike conventional additives, does not alter the viscous properties of oils by introducing solidifying properties. Heat reactive molecules, measuring just 0.01 micrometres, leave no sediment or clogging agents. The molecules assimilate with oils and rapidly migrate onto friction faces, providing stable lubrication, both wet or dry surfaces.

Once attached, the thin anti-corrosive furface modifier penetrates the metal pores creating a mono-molecular surface layer. This prevents friction occurring at extreme pressures and temperatures.

Petrol/Diesel Master's negatively charged molecules in an oil flow are opposed to each other and so generate a new surface boundary under compression. This reaction to heat at 50°C changes the molecules closest to the point of friction and enables bonding to the metal surfaces to take place.

The combined effect is thermodynamic flow and surface streamlining.

Falex Test

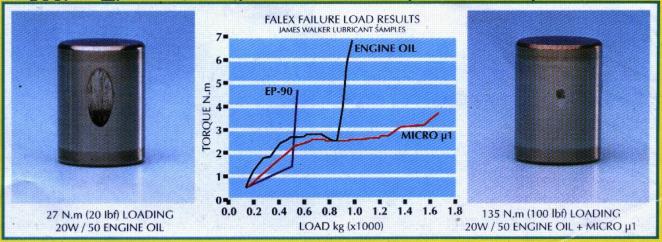

This is a standard method for measuring the extreme pressure (EP) properties of fluid lubricants, and conforms to ASTM D3233. These machines use a rotating pin clamped between two jaws. The hardened steel pin and jaws are immersed in a lubricant sample. The pin is then rotated at 290 rpm, and a load, either constant or incremental, is applied to the jaws by a rachet mechanism. The load-fail value obtained is a measure of the load carrying properties of the test fluid.

For comparison purposes, a top grade 20W50 engine oil and a widely available EP90 gear oil were tested alongside Petrol/Diesel Master. A typical Falex failed load for a straight mineral oil is 270 kg. The EP90 sample failed by seizure at 500 kg. The engine oil gave a better performance, through excessive torque which indicated an large increase in friction, at approximately 910 kg. Petrol/Diesel Master failed by excessive wear at a very high load of 1640 kg, but at a very low torque value, indicating its low friction up until the time of failure.

The following chart shows the relative failure points, together with the results on the pins from the Falex test:

Prices

Petrol/Diesel Master will last per litre about 7,000 miles on large diesel engines and up to 20,000 miles for small gasoline/petrol engines.

Petrol/Diesel Master comes in the following capacities and prices:

100 ml - £ 9.95/$19.99

300 ml - £ 14.99/$29.99

1 litre - £ 44.99/$89.99

2 litre - £ 89.99/$175.99

Email us if you require airmail delivery, and we will let you know the extra cost for airmail delivery. The performance of Petrol/Diesel Master is guaranteed, and if not up to expectations a full refund will be sent to the customer on return of the unused amount. Statutory rights are not affected.